RJP POWDER

RJP 200

RJP POWDER

RJP 400

RJP POWDER

RJP 800

RJG GRANULE

RJG 3300

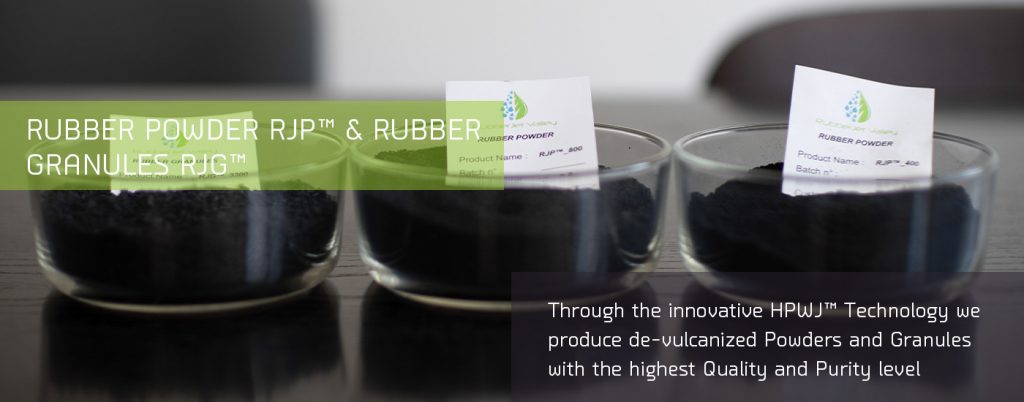

RJP™ & RJG™ PRODUCTS

Our products – The Powder RJP™ and the Granules RJG™ produced by RubberJet using the “High Pressure Water Jet” (H.P.W.J.) technology – were born to respond to the demand of the high quality substitutes for natural rubber.

WHY CHOOSE RJP™ & RJG™?

Discover the unique properties of our products:

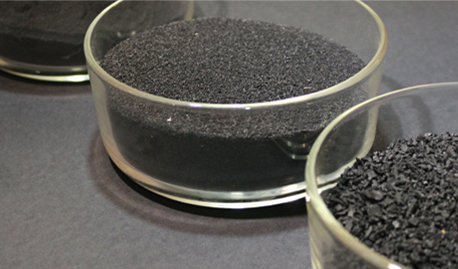

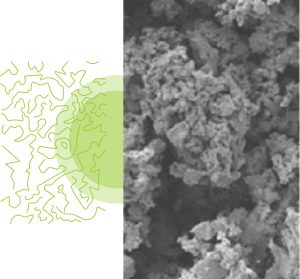

RJP™ and RJG™ have rough surfaces that facilitate the insertion of our product in the compounds making it much more compatible with the NR matrix than the products deriving from traditional technologies.

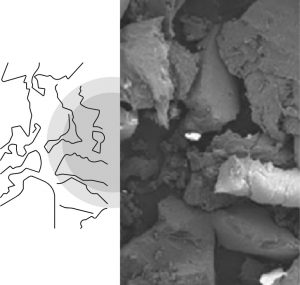

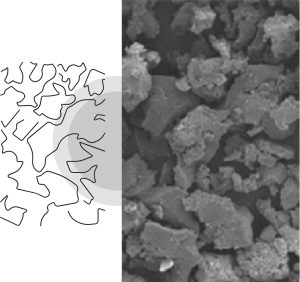

Below images demonstrate the difference between RubberJet powder, Cryogenic powder and Mechanical shredding powder.

MECHANICAL

POWDER

WATERJET

POWDER

CRYOGENIC

POWDER

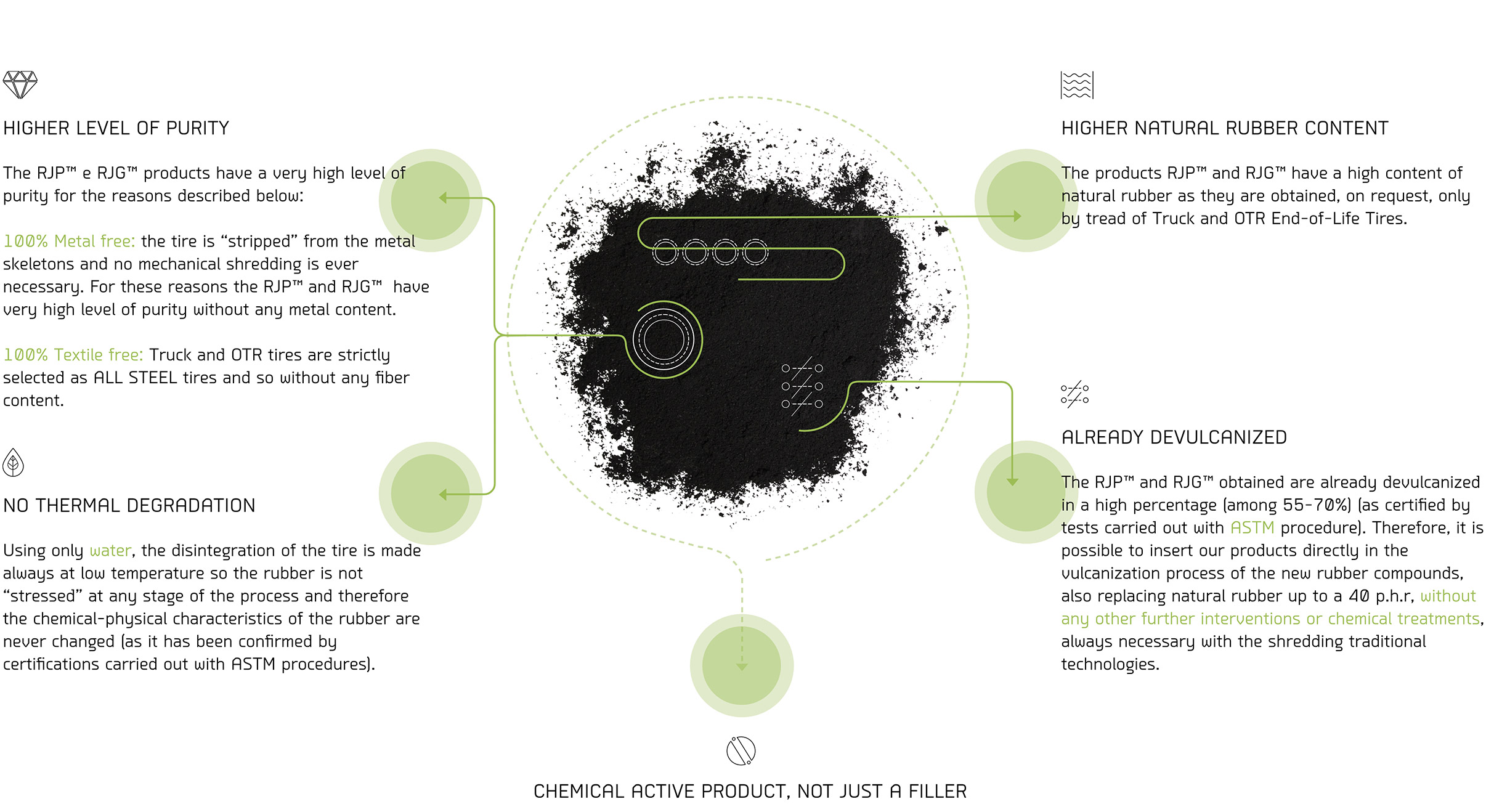

Chemically active product, not just as a filler

The breaking load and tear strength improve if Powder/Granules generated with “H.P.W.J.” technology are incorporated into the NR matrix at levels up to 40 phr.

The reason why a higher percentage of RJPTM and RJGTM can be inserted into the new compounds (in comparison to the recycled rubber deriving from the traditional recycling technologies) is due to their unique qualities and greater activation of the powder/granules because of their rough surfaces and thanks to the higher devulcanization level.

Economic Benefits & Sustainability

Replacing natural rubber with the RJP ™ and RJG ™ products allow the end customer to obtain ECONOMIC BENEFITS due to the lower cost of our product in comparison with natural rubber. It also allows our customers to improve the SUSTAINABILITY metrics metrics of the final products and reduce the CO2 emissions.