HIGH PRESSURE WATER JET technology

The High Pressure Water Jet™ (H.P.W.J™) technology developed by RubberJet is mainly used to recycled medium and large tires, Truck & OTR.

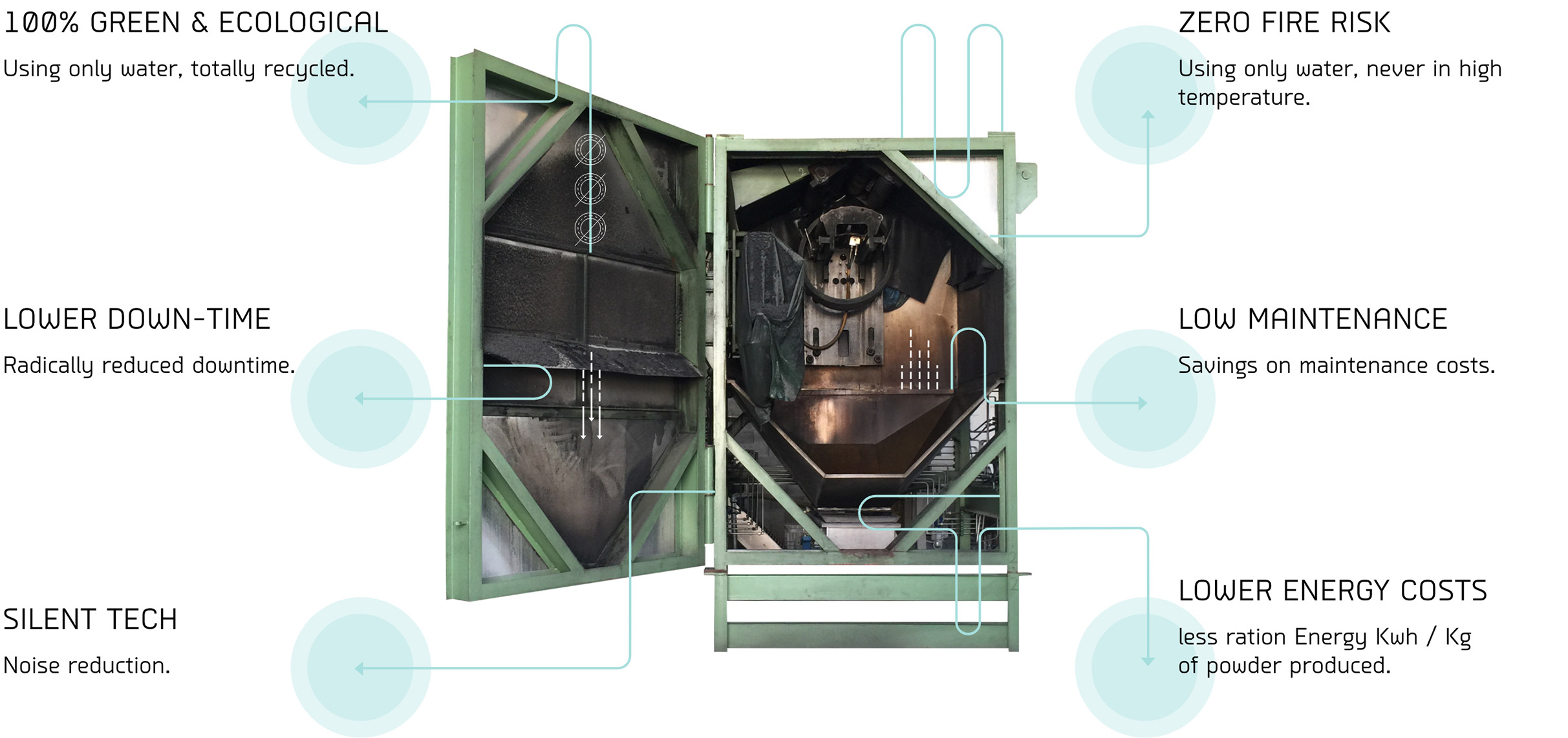

The High Pressure Water Jet™ Technology (H.P.W.J™) is an extremely innovative and completely ecological recycling technology for end of life tires, as it is based on the breakdown of end-of-life tires through an exclusively high-pressure water jet process.

The disintegration and rubber recovery process developed by RubberJet and used on end-of-life tires is based on the use of equipment that uses the energy of water at very high pressure (from 2,000 to 3,000 bar) to break up the tires.

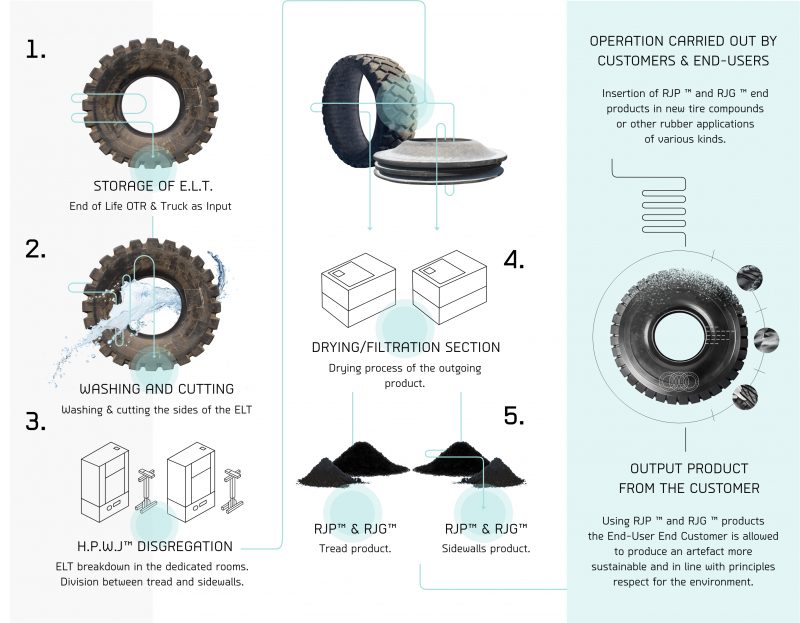

HIGH PRESSURE WATER JET™ Technology Process

Process Flow

PLANT OWNED BY RUBBERJET VALLEY

Full plant view: below is a panoramic image of the industrial plant installed in the province of Verona. The disintegration chamber is visible on the right while the drying and filtering part on the left.

Business Case proposed to Mining Groups

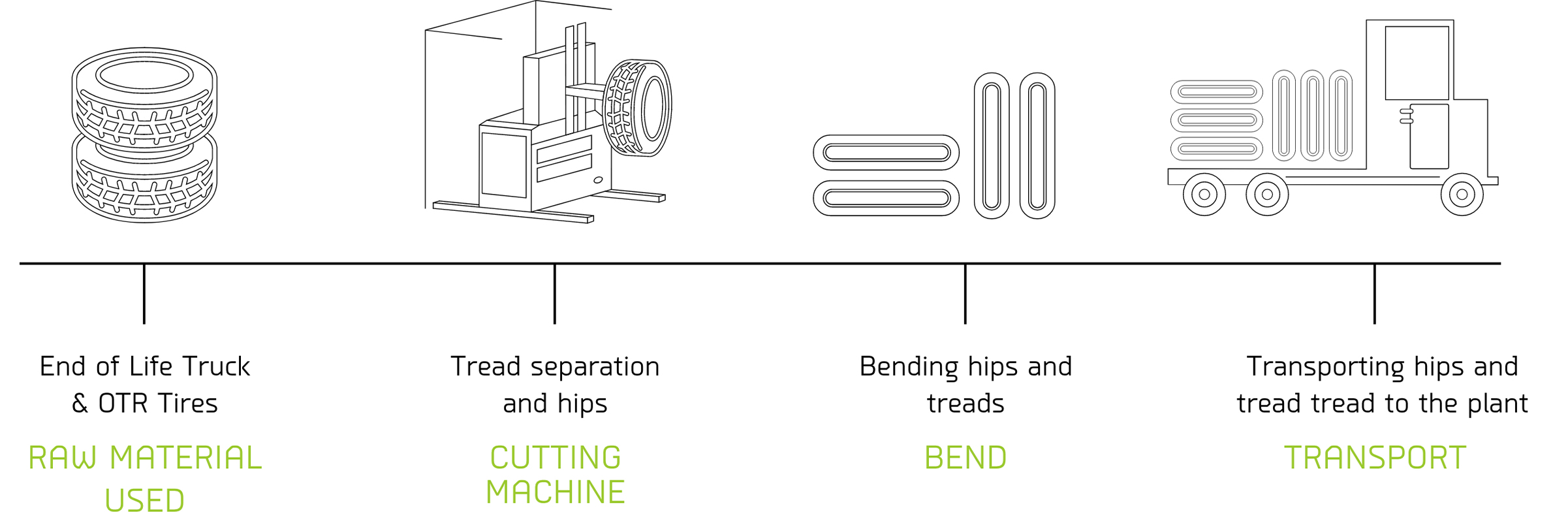

1. phase

Separation, folding and transport of tread and sidewalls

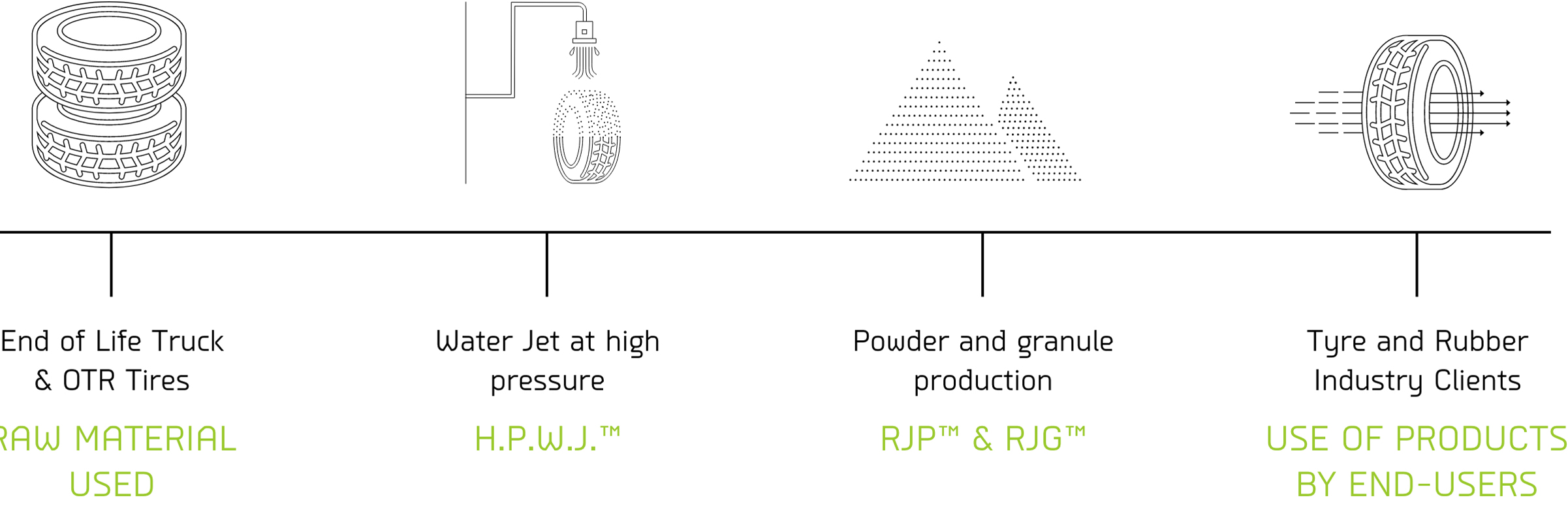

2. phase

RJP™ e RJG™ production

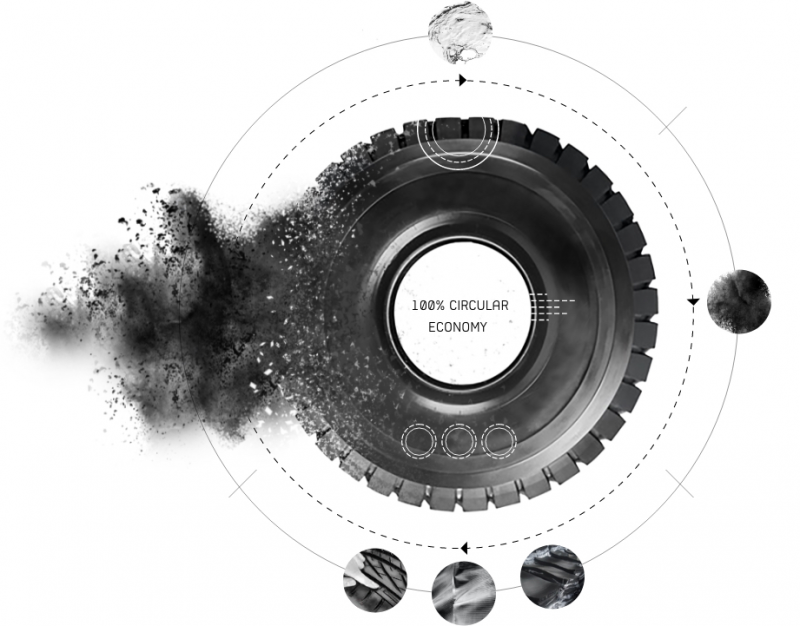

Our mission is to achieve a real Circular Economy in the OTR and Giant Mining OTR tire industry.

RubberJet is a perfect potential local partner that can help mining sites to address the issues related to the disposal of the large dimension end-of-life tyres and move towards a Circular Economy model.

FROM GIANT MINING TIRES TO NEW RUBBER PRODUCTS

For the first time in the world using H.P.W.J. technology we make possible to break-down giant tires through a totally environmentally friendly process which uses only high pressure water jet.

RJP ™ and RJG ™ are certified products of the highest quality and purity that can be used for the creation of new tire compounds and in many other rubber applications.